Finished product will be of round pipe, square and rectangle pipe.

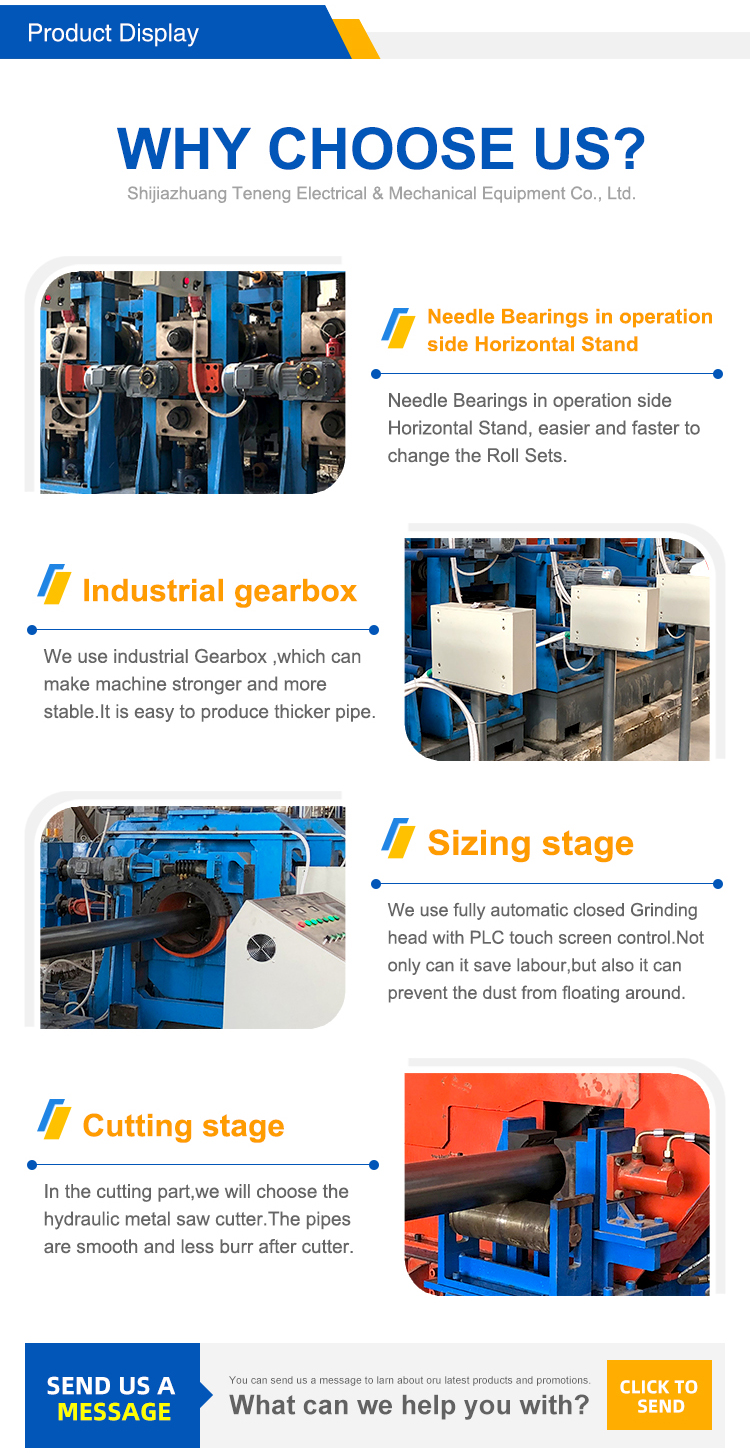

Feeding strip→ Uncoiler→ Peeler→ Five roll Flattening→ shear and end welder→ Spiral accumulator→ Forming → High-frequency induction welding→Removing External burr→ Polishing Roller→ Water Cooling→ Sizing→ Cutting Saw→ Pullout roller table→ Weighing and Measuring→ Painting and Marking→ Packing→ Warehousing

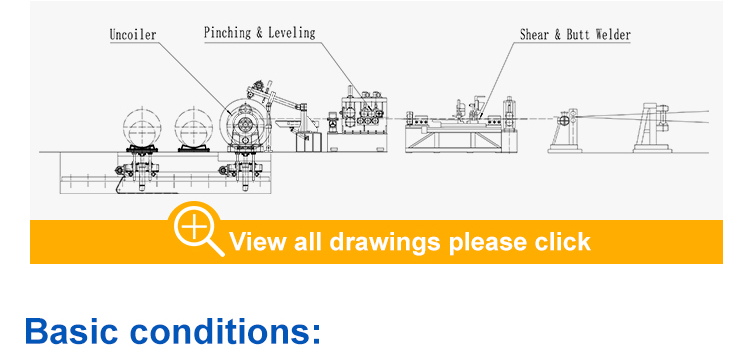

| Strip Steel Coil | |

| Material | Low carbon steel and low alloy steel |

| Strip steel thickness | 4.0~12.0mm |

| Strip steel width | 360~1200 mm |

| Inner Diameter | Φ580mm~Φ760mm |

| Outer Diameter | Φ900mm~Φ2200mm |

| Max Weight | Max.25 ton |

| Steel Pipe Specification | |

| Square Pipe | 90×90~300×300 mm |

| Thickness | 4.0~12.0 mm |

| Rectangle Pipe | 120×80~200×400 mm |

| Thickness | 4.0~12.0 mm |

| Length Scope of Pipe | 6~12m |

| Tolerance | ±3 mm |

| Moulding mothed | Square and rectangle |

| Welding mothed | H.F. welding |

| Feeding direction | Right or left side feeding |

| Stand operation level | +950mm |

| Power | |

| Voltage | AC380V±10% |

| Phase | 3 phase |

| Frequency | 50Hz±1.0% |

| Control Power | |

| Voltage | AC220V±10% |

| Phase | Single phase |

| Frequency | 50Hz±1.0% |

| Power capacity installed | Appro. 3600KW |

| Pressure | 0.4Mpa |

| Rate of flow | 4m3/h |

| Poduction capacity | 100000ton/year |

| Line speed | 10-40m/min |