The mill is intended for manufacturing of round pipe ofΦ12-Φ50mmwith thickness of 0.5-2.0mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

Finished product will be of round, square or rectangular pipe.

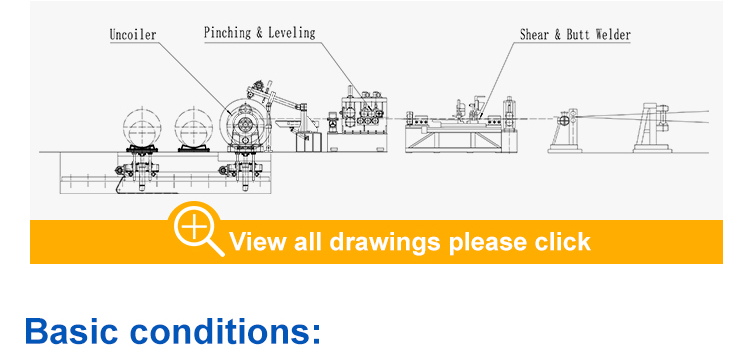

Scroll up→Uncoil→Flattening→Cutting head, tail→Strip Steel head-tail butt welding→Looping storage→Confectioning→High-frequency induction welding→ Removing external burr →Cooling→Forming→Cutting→Checking & Collecting → Binding → Weighing → Marking → Accessing Warehouse

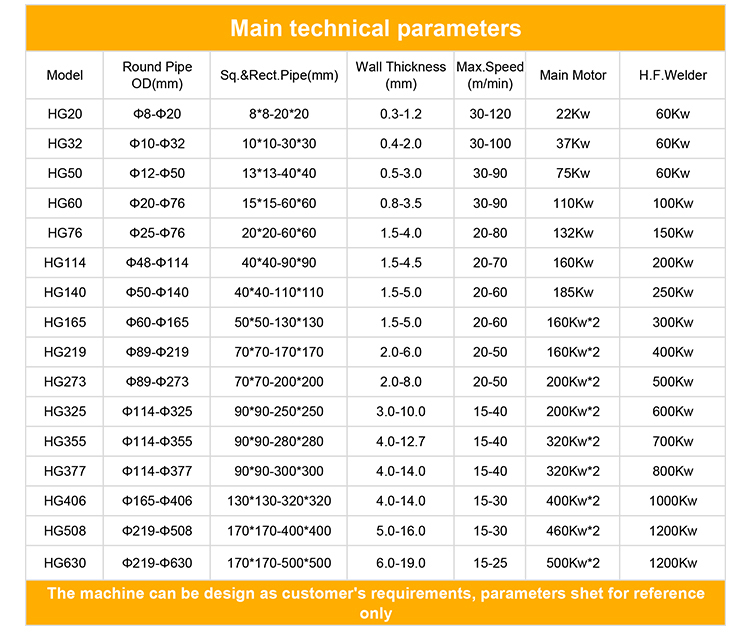

| Steel Pipe Specification | |

| Round Pipe diameter | Φ89-Φ273 |

| Pipe Thickness | 0.5– 2.0mm |

| Square and rectangle pipe | 70*70-200*200 |

| Pipe Thickness | 2.0-8.0 |

| Pipe Length | 6-12m |

| Length Tolerance | 0-6mm |

| Steel Tape Specification | |

| Material | Carbon steel (δb≤500Mpa, δs≤235Mpa) |

| Inner diameter | Φ470-Φ510mm |

| Outer diameter | Φmax=1800mm |

| Strip steel width | 40mm-60mm |

| Strip steel thickness | 1.2mm-4.0mm |

| The maximum weight | 1.5.0tons |

| Electric installed capacity | appro.250KW |

| Line Speed | 20-50m/min |