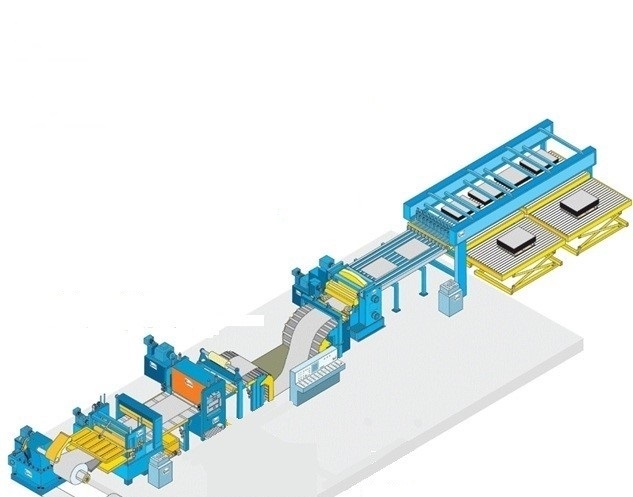

Uncoiler→ shovel board device → Flattening →Accumulator→Centering device→Fixed length and feeding device→cutting machine→convey table→Precision leveler→sending roller→StackingFrame

| Raw material: | Black steel,blue steel, galvanized steel,cold-rollingsteel, prepainted steel, pickling coil |

| Thickness of steel strip: | 0.4~3.2mm |

| Width of steel strip: | 800~1500mm |

| Inner diameter of strip coil: | Φ508-Φ610mm |

| Outer diameter of strip coil: | Φ1000-Φ1800mm |

| Max quantity of strip coil: | 30tons |

| Cut Length: | 500~6000mm |

| Cut Accuracy: | ±1.0mm |

| Speed: | Max 60m/min |

| Input Power: | 380 Volt, 3 phase, 4 lines, 50Hz. |

| Feeding Direction: | Left side or right side |

| Cutting line technical style: | Automaticfixed length and feedingfeed length, fixed shear. |

| Composition | 1. V-shape coil storage 2.Coil loading cart 3.Hydraulic double head uncoiler 4.Feeding conducting plate device 5.Pinch device 6.Fifteen-roll straightening machine quadruple style 7.Mid-bridge 8.Side guiding positioning device 9.Five-roll precise leveler 10.Pinch sizing device 11.Transverse shear 12.Delivery platform 13.Hydraulic loading lifting platform 14.Unloading stand 15.Unloading Car 16.Hydraulic and pneumatic system 17.Electric control system |